Knife Over Roll

Coating is applied to the substrate which then passes through a ‘gap’ between a ‘knife’ and a support roller. As the coating and substrate pass through, the excess is scraped off. This process can be used for high viscosity coatings and very high coat weights, such as plastisols and rubber coatings.

Knife Over Air

Coating is applied to the substrate and passes under a knife which presses directly on the fabric. The knife is positioned between two support rolls and fabric tension helps control the application level.

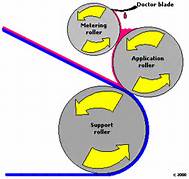

Roller (Kiss Coating)

Procedure for coating a substrate web in which the coating roll carries a metered film of coating material; part of the film transfers to the web, part remains on the roll.

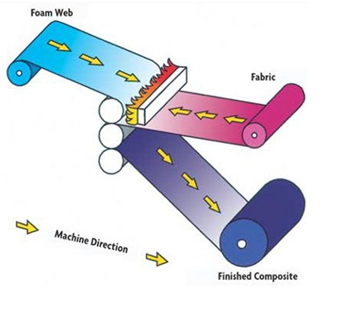

Foam Generator

Foamed water soluble or water dispersible chemicals at very low moisture levels are applied onto or into substrates such as textiles, non-woven, paper, etc. Chemical migration in the substrate is virtually eliminated by the low moisture levels.

Pad/Bath

The substrate is dipped into a bath of the coating, which is normally of a low viscosity to enable the coating to run back into the bath as the substrate emerges. This process is frequently used on porous substrates.

Steam Table

Passing fabric over coils with live steam to provide heat or moist heat. Energy applied in this manner can be used to condition fabric prior to further processing or provide a means of fixation for certain chemical applications. Passing fabric over closed steam coils acts as a means of preheating fabric prior to tentering.